We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Scrub Up!

Proper care of veterinary surgical instruments is fundamental to infection prevention

and veterinary clinic operational efficiency.

New surgical instruments are a significant investment for your practice, so it only makes sense to proactively protect these valuable resources.

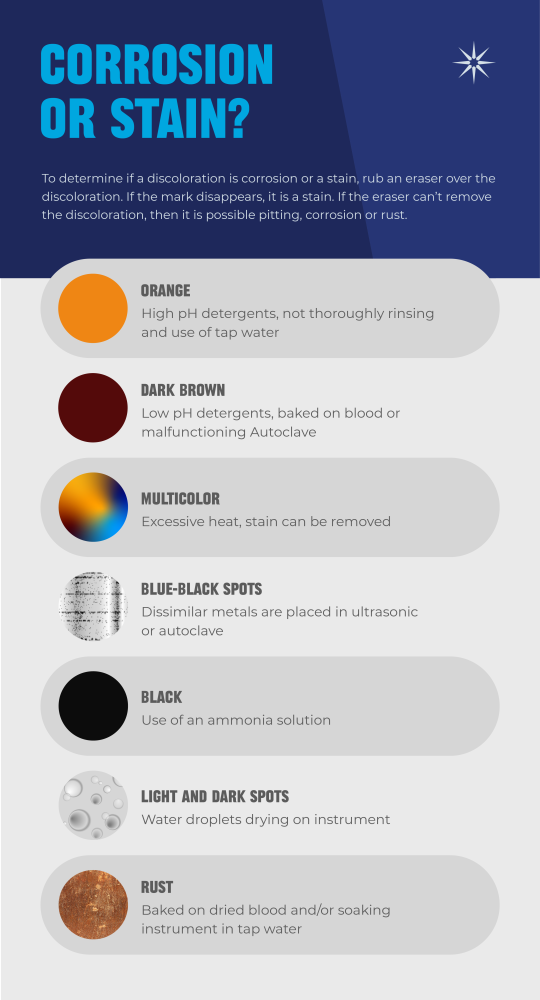

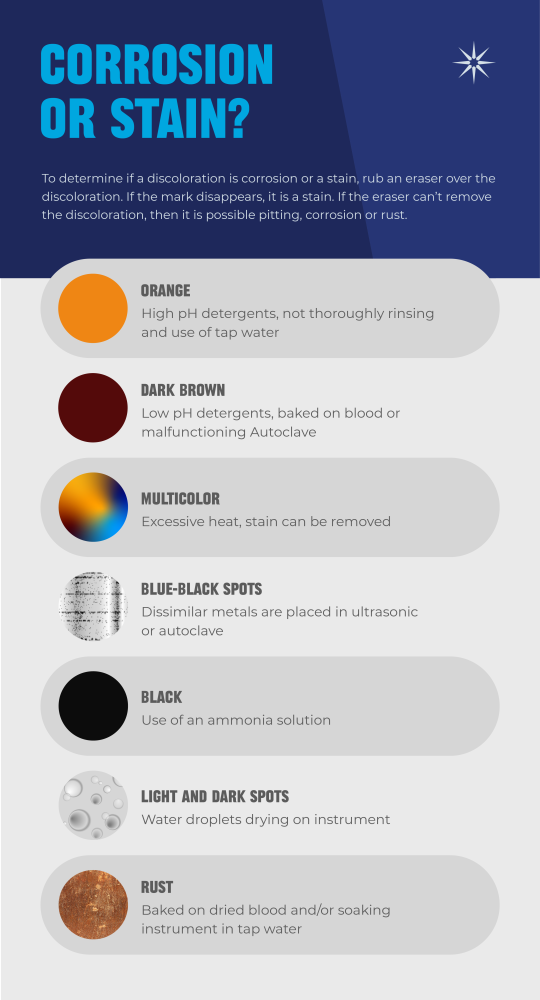

Most veterinary surgical instruments are made from stainless steel which is resistant to rust and staining when properly maintained. However, without adequate maintenance, even the highest-quality instruments can stain, corrode and experience mechanical failure.

The best time to get ahead of these issues is upon receiving new surgical instruments. Use these tips to ensure a long-life for these important tools.

Wash immediately

Don't waste precious time waiting in a phone tree. With MAI Animal Health, you speak to real people with technical expertise who provide personalized service for your practice. We know our products in-depth and can offer insights into proper usage and troubleshooting techniques.

Washing instruments with dish detergent immediately after receiving is often overlooked. This step should occur before the first autoclave and use, since it plays a significant role in maintaining the performance of high-quality instruments.

The following cleaning process serves multiple functions:

- Removal of manufacturing residues: New instruments may carry residues from the manufacturing process, such as oils, greases and other contaminants. Residual oils can become discolored when autoclaved. Washing with a grease-cutting dish detergent helps remove these residues, ensuring that the instruments are clean and ready for sterilization.

- Ensuring effective sterilization: Autoclaving uses high-pressure steam to sterilize instruments — killing bacteria, viruses and other microorganisms. For autoclaving to be effective, instruments must be free of materials that could shield microorganisms from the steam.

Once instruments are ready for daily use, follow these best practices for pre-autoclave washing:

- Don't let blood dry: Dried blood is a common instrument contaminant/staining agent. To avoid this concern, place surgical instruments in hot, soapy water immediately after concluding a procedure, with an initial wash occurring within 20 minutes. This protocol improves and expedites the cleaning process.

- Ultrasonic cleaning: An ultrasonic cleaner can provide additional cleaning alongside hand washing. Ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles that dislodge contaminants from instrument surfaces. This method is particularly effective for complex instruments with hard-to-reach areas.

- Rinse thoroughly: After washing with dish detergent, it is crucial to rinse instruments thoroughly with distilled water. Tap water may contain minerals and impurities that can cause staining and corrosion. Distilled water ensures that no residues are left on the instruments.

- Drying: Proper drying prevents water spots and corrosion. Instruments should be dried with a clean, lint-free cloth or air-dried using a medical-grade dryer. Ensuring the instruments are completely dry before autoclaving prevents water from interfering with the sterilization process.

Proper care and maintenance can significantly impact the performance and longevity of surgical instruments. By incorporating the practice of first-time washing into the instrument care routine, veterinary clinics can prevent unnecessary wear on their instruments to enhance their operational efficiency and provide the highest quality of care to their patients.

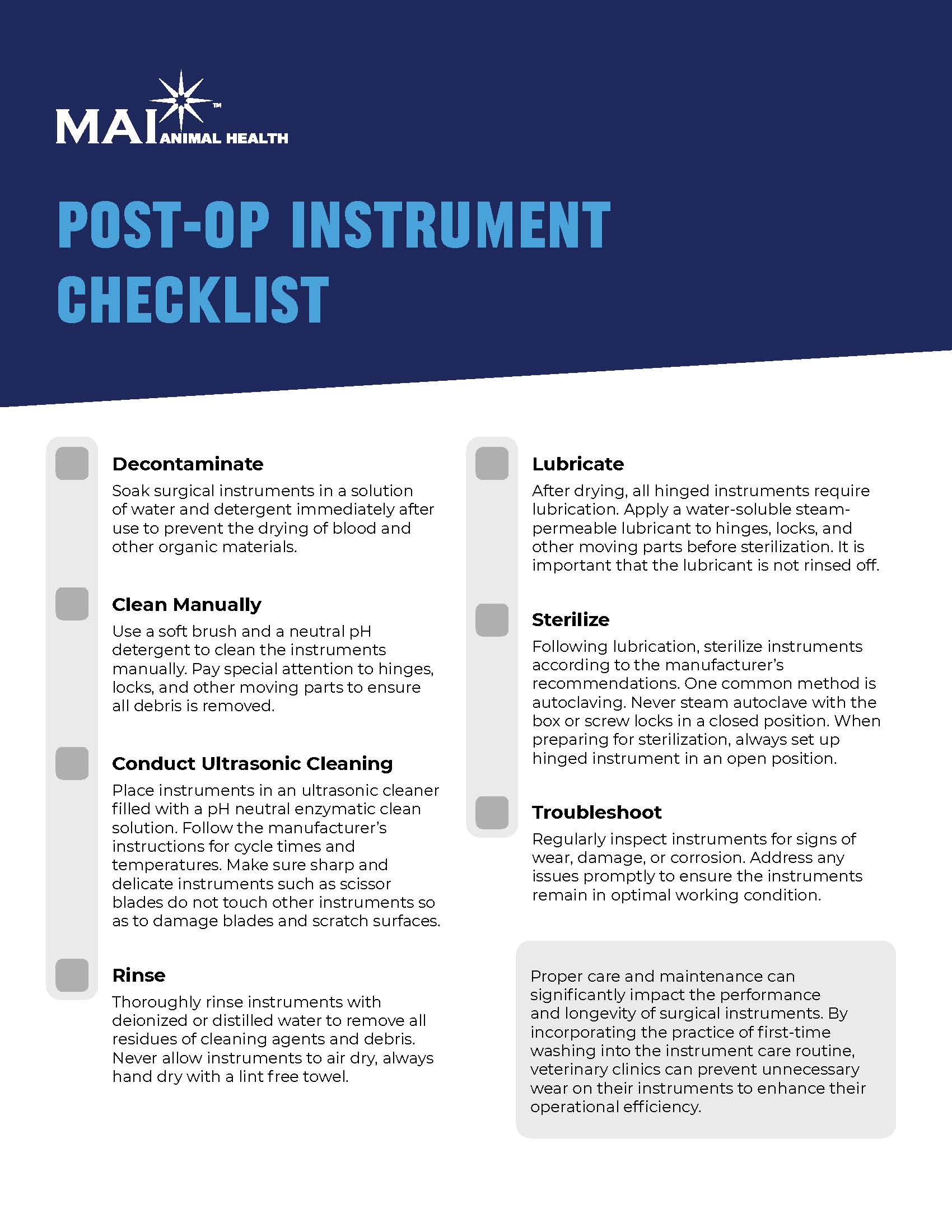

Below is a printable checklist for post-op surgical instrument care: